エルボ配管内の流れ (流れ)¶

シミュレーション名: flow__in_a_curved_pipe_XYZ3D

シミュレーション体系¶

Navier-Stokes方程式

エルボの内径、外径はそれぞれ 160 mm, 200 mm ( 半径はそれぞれ 80 mm, 100 mm ).

エルボは直角 ( 90 deg )に、曲率半径は 1.0 m で曲がる.

曲がり部分の両端に 1.0 m の直管部分がある.

流入側の配管外側には、外径 300mm のヒーターを取り付けている(本問題には無関係).

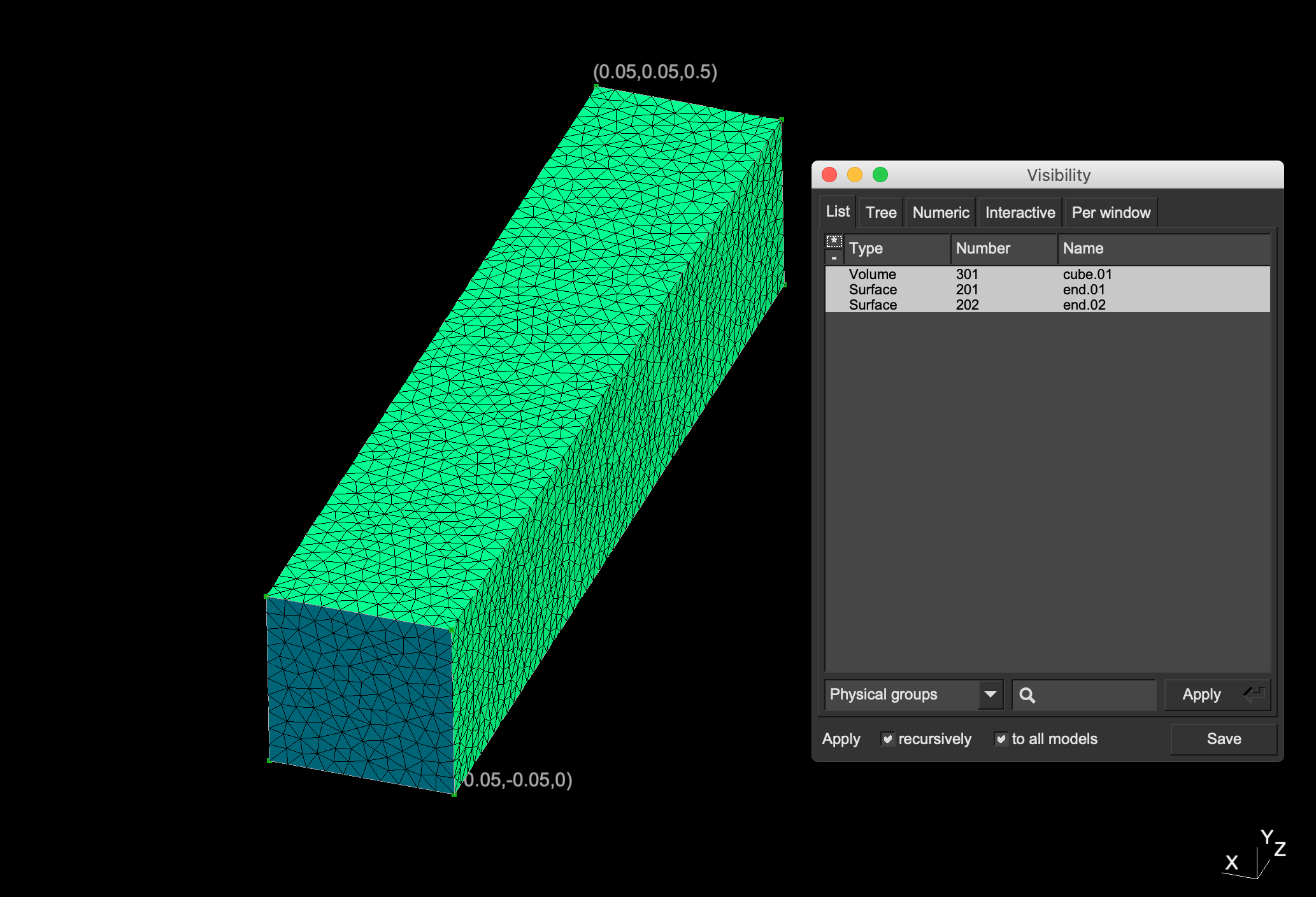

メッシュ¶

メッシュ生成スクリプト ( mesh.py )

mesh.py ( flow__in_a_curved_pipe_XYZ3D )¶

import numpy as np

import os, sys

import gmsh

# ========================================================= #

# === make__geometry === #

# ========================================================= #

def make__geometry( dimtags={} ):

surfDim, voluDim = 2, 3

# ------------------------------------------------- #

# --- [1] parameter --- #

# ------------------------------------------------- #

radius_1 = 0.1

radius_2 = 0.08

radius_3 = 0.15

heater_s = 0.30

heater_e = 0.70

angle = 90.0 * np.pi/180.0

# ------------------------------------------------- #

# --- [2] design pipe1 --- #

# ------------------------------------------------- #

cylinder_1s = gmsh.model.occ.addCylinder( 0,0,0, 1.0, 0,0, radius_1 )

disk_1 = gmsh.model.occ.addDisk( 1,0,0, radius_1, radius_1 )

rotate = gmsh.model.occ.rotate( [(surfDim,disk_1)], 1,0,0, 0,1,0, angle )

revolve_1 = gmsh.model.occ.revolve( [(surfDim,disk_1)], 1,1,0, 0,0,1, angle )

cylinder_1e = gmsh.model.occ.addCylinder( 2,1,0, 0,1,0, radius_1 )

object_1 = [ (dim,tag) for dim,tag in revolve_1 if ( dim == 3 ) ]

tools_1 = [ (voluDim,cylinder_1s), (voluDim,cylinder_1e) ]

gmsh.model.occ.synchronize()

pipe1,maps = gmsh.model.occ.fuse( object_1, tools_1, removeObject=True, removeTool=True )

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [3] design pipe2 --- #

# ------------------------------------------------- #

cylinder_2s = gmsh.model.occ.addCylinder( 0,0,0, 1.0, 0,0, radius_2 )

disk_2 = gmsh.model.occ.addDisk( 1,0,0, radius_2, radius_2 )

rotate = gmsh.model.occ.rotate( [(surfDim,disk_2)], 1,0,0, 0,1,0, angle )

revolve_2 = gmsh.model.occ.revolve( [(surfDim,disk_2)], 1,1,0, 0,0,1, angle )

cylinder_2e = gmsh.model.occ.addCylinder( 2,1,0, 0,1,0, radius_2 )

object_2 = [ (dim,tag) for dim,tag in revolve_2 if ( dim == 3 ) ]

tools_2 = [ (voluDim,cylinder_2s), (voluDim,cylinder_2e) ]

gmsh.model.occ.synchronize()

pipe2,maps = gmsh.model.occ.fuse( object_2, tools_2, removeObject=True, removeTool=True )

gmsh.model.occ.synchronize()

pipe1,maps = gmsh.model.occ.cut ( pipe1, pipe2, removeObject=True, removeTool=False )

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [4] design heater --- #

# ------------------------------------------------- #

length = heater_e - heater_s

cylinder_3o = gmsh.model.occ.addCylinder( heater_s,0,0, length, 0,0, radius_3 )

cylinder_3i = gmsh.model.occ.addCylinder( heater_s,0,0, length, 0,0, radius_1 )

heater,maps = gmsh.model.occ.cut( [(voluDim,cylinder_3o)], [(voluDim,cylinder_3i)], \

removeObject=True, removeTool=True )

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [3] register dimtags --- #

# ------------------------------------------------- #

dimtags["pipe"] = pipe1

dimtags["fluid"] = pipe2

dimtags["heater"] = heater

dimtags["inlet"] = [(2,9)]

dimtags["outlet"] = [(2,10)]

dimtags["inner_pipe"] = [(2,6),(2,7),(2,8)]

dimtags["outer_pipe"] = [(2,23),(2,24),(2,25),(2,26)]

dimtags["pipeEnd_inlet"] = [(2,27)]

dimtags["pipeEnd_outlet"] = [(2,28)]

dimtags["heater_contact"] = [(2,19)]

dimtags["heater_surface"] = [(2,20),(2,21),(2,22)]

return( dimtags )

# ========================================================= #

# === 実行部 === #

# ========================================================= #

if ( __name__=="__main__" ):

# ------------------------------------------------- #

# --- [1] initialization of the gmsh --- #

# ------------------------------------------------- #

gmsh.initialize()

gmsh.option.setNumber( "General.Terminal", 1 )

gmsh.option.setNumber( "Mesh.Algorithm" , 5 )

gmsh.option.setNumber( "Mesh.Algorithm3D", 4 )

gmsh.option.setNumber( "Mesh.SubdivisionAlgorithm", 0 )

gmsh.model.add( "model" )

# ------------------------------------------------- #

# --- [2] Modeling --- #

# ------------------------------------------------- #

sample__model = "make" # -- [ "import" / "make" ] -- #

if ( sample__model == "import" ):

dimtagsFile = None

stpFile = "msh/model.stp"

import nkGmshRoutines.import__stepFile as isf

dimtags = isf.import__stepFile( inpFile=stpFile, dimtagsFile=dimtagsFile )

elif ( sample__model == "make" ):

dimtags = {}

dimtags = make__geometry( dimtags=dimtags )

gmsh.model.occ.synchronize()

gmsh.write( "msh/model.stp" )

gmsh.model.occ.synchronize()

gmsh.model.occ.removeAllDuplicates()

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [3] Mesh settings --- #

# ------------------------------------------------- #

mesh_from_config = True # from nkGMshRoutines/test/mesh.conf, phys.conf

uniform_size = 0.05

if ( mesh_from_config ):

meshFile = "dat/mesh.conf"

physFile = "dat/phys.conf"

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( meshFile=meshFile, physFile=physFile, dimtags=dimtags )

else:

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( uniform=uniform_size, dimtags=dimtags )

# ------------------------------------------------- #

# --- [4] post process --- #

# ------------------------------------------------- #

gmsh.model.occ.synchronize()

gmsh.model.mesh.generate(3)

gmsh.write( "msh/model.msh" )

gmsh.finalize()

phys.conf

phys.conf ( flow__in_a_curved_pipe_XYZ3D )¶

# <names> key type dimtags_keys physNum

fluid volu [fluid] 301

pipe volu [pipe] 302

heater volu [heater] 303

inlet surf [inlet] 201

outlet surf [outlet] 202

inner_pipe surf [inner_pipe] 203

outer_pipe surf [outer_pipe] 204

pipeEnd_inlet surf [pipeEnd_inlet] 205

pipeEnd_outlet surf [pipeEnd_outlet] 206

heater_surface surf [heater_surface] 207

heater_contact surf [heater_contact] 208

mesh.conf

mesh.conf ( flow__in_a_curved_pipe_XYZ3D )¶

# <names> key physNum meshType resolution1 resolution2 evaluation

fluid 301 constant 0.02 - -

pipe 302 constant 0.02 - -

heater 303 constant 0.03 - -

inlet 201 constant 0.0 - -

outlet 202 constant 0.0 - -

inner_pipe 203 constant 0.0 - -

outer_pipe 204 constant 0.0 - -

pipeEnd_inlet 205 constant 0.0 - -

pipeEnd_outlet 206 constant 0.0 - -

heater_surface 207 constant 0.0 - -

heater_contact 208 constant 0.0 - -

生成したメッシュを次に示す.

Elmer シミュレーションファイル¶

シミュレーションファイル ( ns.sif )を以下に示す.

ns.sif ( flow__in_acurved_pipe_XYZ3D )¶

include "./msh/model/mesh.names"

Header

CHECK KEYWORDS Warn

Mesh DB "." "msh/model"

Include Path ""

Results Directory "out/"

End

Simulation

Max Output Level = 3

Coordinate System = string "Cartesian"

Coordinate Mapping(3) = 1 2 3

Simulation Type = "Transient"

TimeStepping Method = BDF

BDF Order = 2

Timestep sizes(1) = 0.1

Timestep Intervals(1) = 50

Steady State Max Iterations = 1

Post File = output.vtu

End

Constants

Gravity(4) = 0 0 -1 9.82 !! m/s^2

End

Solver 1

Equation = Navier-Stokes

Linear System Solver = Iterative

Linear System Direct Method = UMFPACK

Linear System Iterative Method = BiCGStab

Linear System Convergence Tolerance = 1.0e-6

Linear System Max Iterations = 5000

Linear System Preconditioning = ILUT

Nonlinear System Convergence Tolerance = Real 1.0e-7

Nonlinear System Max Iterations = Integer 1000

Nonlinear System Relaxation Factor = Real 1.0

Nonlinear System Newton After Iterations = 15

Nonlinear System Newton After Tolerance = 1.0e-3

Steady State Convergence Tolerance = 1.0e-5

stabilize = True

Div Discretization = False

End

Body 1

Name = "fluid"

Target Bodies(1) = $fluid

Equation = 1

Material = 1

End

Equation 1

Name = "Fluid"

Active Solvers(1) = 1

Navier-Stokes = True

End

Material 1

Name = "Air"

Density = 1.2e0 !! kg/m3

Viscosity = 1.0e-3 !!

End

Boundary Condition 1

Name = "inlet"

Target Boundaries(1) = $inlet

Velocity 1 = 1.0

Velocity 2 = 0

Velocity 3 = 0

End

Boundary Condition 2

Name = "outlet"

Target Boundaries(1) = $outlet

End

Boundary Condition 3

Name = "inner_pipe"

Target Boundaries(1) = $inner_pipe

!! Velocity 1 = 0

!! Velocity 2 = 0

!! Velocity 3 = 0

End