物体から流体への熱伝達(自然対流冷却)¶

シミュレーション名 :: heatTransfer__box_in_water_XY2D

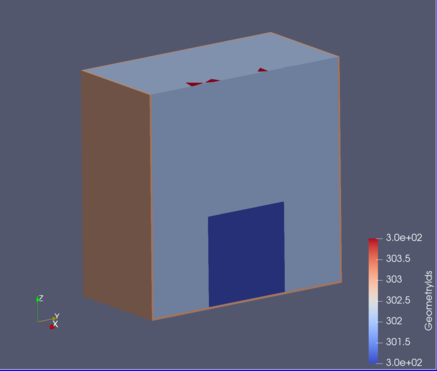

シミュレーション体系¶

基本方程式は、 Navier-Stokes方程式 と 標準k-ε方程式 と 熱輸送方程式

流体は、 非圧縮 , 標準k-εモデル を取扱い、対象は空気とする.

計算対象は、2次元の閉じた立方体の箱の中にバルク鉄塊をおいた際の熱伝達をみる.

2次元 長さ 200 [mm], 幅 200 [mm]、高さ 200 [mm]、厚み 10 [mm] の中空の箱の中央下部に、長さ 50 [mm] 、幅 50 [mm]、高さ 50 [mm] の鉄塊(SS400)を置く.

標準k-εモデル を用いて、壁境界は 垂直方向流速にゼロを課した (Normal-Tangential).

全領域の初期条件は、流速は0、k=0.00457, epsilon=1e-4 とおいている.

物性条件¶

Target |

Parameters |

Value |

Unit |

Description |

|---|---|---|---|---|

空気 |

Density |

1.2e+0 |

kg/m3 |

密度 |

viscosity |

1.0e-5 |

Pa.s |

粘度 |

|

KE SigmaK |

1.0 |

|||

KE SigmaE |

1.3 |

|||

KE C1 |

1.44 |

係数C1 |

||

KE C2 |

1.92 |

係数C1 |

||

KE Cmu |

0.09 |

係数Cmu |

||

KE Clip |

1.0e-6 |

|||

Viscosity Model |

K-Epsilon |

使用するモデル |

||

Heat Conductivity |

0.0257 |

W/m.K |

熱伝導度 |

|

Heat Capacity |

1.005e+3 |

J/kg.K |

比熱 |

|

Density |

1.166e+0 |

kg/m3 |

密度 |

|

SS400 |

Heat Conductivity |

51.6 |

W/m.K |

熱伝導率 |

Heat Capacity |

473.0 |

J/kg.K |

比熱 |

|

Density |

7.85e+3 |

kg/m3 |

密度 |

メッシュ¶

メッシュ生成スクリプト ( mesh.py )

import numpy as np

import os, sys

import gmsh

import nkGmshRoutines.define__geometry_2d as dg2

import nkGmshRoutines.load__dimtags as ldt

# ========================================================= #

# === 実行部 === #

# ========================================================= #

if ( __name__=="__main__" ):

# ------------------------------------------------- #

# --- [1] initialization of the gmsh --- #

# ------------------------------------------------- #

gmsh.initialize()

gmsh.option.setNumber( "General.Terminal", 1 )

gmsh.option.setNumber( "Mesh.Algorithm" , 5 )

gmsh.option.setNumber( "Mesh.Algorithm3D", 4 )

gmsh.option.setNumber( "Mesh.SubdivisionAlgorithm", 0 )

gmsh.model.add( "model" )

# ------------------------------------------------- #

# --- [2] Modeling --- #

# ------------------------------------------------- #

dimtags = {}

inpFile = "dat/geometry.conf"

bdrFile = "dat/boundary.json"

dimtags = dg2.define__geometry_2d( inpFile=inpFile, dimtags=dimtags )

dimtags = ldt.load__dimtags( dimtags=dimtags, inpFile=bdrFile )

gmsh.model.occ.synchronize()

gmsh.model.occ.removeAllDuplicates()

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [3] Mesh settings --- #

# ------------------------------------------------- #

mesh_from_config = True # from nkGMshRoutines/test/mesh.conf, phys.conf

uniform_size = 0.05

if ( mesh_from_config ):

meshFile = "dat/mesh.conf"

physFile = "dat/phys.conf"

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( meshFile=meshFile, physFile=physFile, \

dimtags=dimtags, target="surf" )

else:

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( uniform=uniform_size, dimtags=dimtags )

# ------------------------------------------------- #

# --- [4] post process --- #

# ------------------------------------------------- #

gmsh.model.occ.synchronize()

gmsh.model.mesh.generate(2)

gmsh.write( "msh/model.msh" )

gmsh.finalize()

geometry.conf

# <define> @cntnr.Lx = 200e-3

# <define> @cntnr.Ly = 200e-3

# <define> @cntnr.thick = 10e-3

# <define> @cntnr.x0 = (-0.5) * @cntnr.Lx

# <define> @cntnr.y0 = 0.0

# <define> @cntnr.dx = @cntnr.Lx

# <define> @cntnr.dy = @cntnr.Ly

# <define> @fluid.Lx = @cntnr.Lx - 2.0 * @cntnr.thick

# <define> @fluid.Ly = @cntnr.Ly - 2.0 * @cntnr.thick

# <define> @fluid.x0 = (-0.5) * @fluid.Lx

# <define> @fluid.y0 = @cntnr.thick

# <define> @fluid.dx = @fluid.Lx

# <define> @fluid.dy = @fluid.Ly

# <define> @metal.Lx = 50e-3

# <define> @metal.Ly = 50e-3

# <define> @metal.x0 = (-0.5) * @metal.Lx

# <define> @metal.y0 = @cntnr.thick

# <define> @metal.dx = @metal.Lx

# <define> @metal.dy = @metal.Ly

# <names> key geometry_type x0 y0 dx dy

metal quad @metal.x0 @metal.y0 @metal.dx @metal.dy

fluid.00 quad @fluid.x0 @fluid.y0 @fluid.dx @fluid.dy

cntnr.00 quad @cntnr.x0 @cntnr.y0 @cntnr.dx @cntnr.dy

# <names> key boolean_type targetKeys toolKeys removeObject removeTool

container cut [container.00] [fluid.00] True False

fluid cut [fluid.00] [metal] True False

boundary.json

{

"metal" : [ [2,1] ],

"fluid": [ [2,2] ],

"container": [ [2,3] ],

"metal_fluid": [ [1,5], [1,6], [1,7] ],

"metal_container": [ [1,13] ],

"fluid_container": [ [1,1], [1,2], [1,3], [1,4], [1,8] ],

"container_outside": [ [1,9], [1,10], [1,11], [1,12] ]

}

phys.conf

# <names> key type dimtags_keys physNum

metal surf [metal] 201

fluid surf [fluid] 202

container surf [container] 203

metal_fluid line [metal_fluid] 101

metal_container line [metal_container] 102

fluid_container line [fluid_container] 103

container_outside line [container_outside] 104

mesh.conf

# <names> key physNum meshType resolution1 resolution2 evaluation

metal 201 constant 0.01 - -

fluid 202 constant 0.01 - -

container 203 constant 0.01 - -

metal_fluid 101 constant 0.0 - -

metal_container 102 constant 0.0 - -

fluid_container 103 constant 0.0 - -

container_outside 104 constant 0.0 - -

生成したメッシュを次に示す.

elmer シミュレーション設定¶

elmer シミュレーション設定ファイルを以下に示す.

!! ========================================================= !!

!! === time-evolution of natural cooling by Boussinesq === !!

!! ========================================================= !!

include "./msh/model/mesh.names"

Header

CHECK KEYWORDS Warn

Mesh DB "." "msh/model"

Include Path ""

Results Directory "out/"

End

!! ------------------------------------------------- !!

!! --- [1] Simulation --- !!

!! ------------------------------------------------- !!

Simulation

Max Output Level = 3

Coordinate System = "Cartesian"

Coordinate Mapping(3) = 1 2 3

Simulation Type = "Transient"

TimeStepping Method = BDF

BDF Order = 2

Timestep sizes(1) = 1e-1

Timestep Intervals(1) = 1000

Steady State Max Iterations = 200

Post File = heatTransfer.vtu

End

Constants

Stefan Boltzmann = 5.6703e-8 !! -- [ W / m^2 K^4 ] -- !!

gravity(4) = 0 -1 0 9.82 !! -- [ m/s^2 ] -- !!

End

!! ------------------------------------------------- !!

!! --- [2] Solver & Equation --- !!

!! ------------------------------------------------- !!

Solver 1

Equation = k-epsilon

Procedure = "KESolver" "KESolver"

Stabilize = True

Linear System Solver = Direct

Linear System Direct Method = String "umfpack"

!! Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 10000

Linear System Preconditioning = ILUT

Linear System Convergence Tolerance = 1.0e-5

Nonlinear System Max Iterations = 1

Nonlinear System Convergence Tolerance = 1.0e-5

Nonlinear System Relaxation Factor = 0.5

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Newton After Iterations = 10000

Steady State Convergence Tolerance = 1.0e-5

End

Solver 2

Equation = Navier-Stokes

Procedure = "FlowSolve" "FlowSolver"

Stabilize = True

Linear System Solver = Direct

Linear System Direct Method = String "umfpack"

!! Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 10000

Linear System Convergence Tolerance = 1.0e-5

Linear System Preconditioning = ILUT

Nonlinear System Max Iterations = 1

Nonlinear System Convergence Tolerance = 1.0e-5

Nonlinear System Relaxation Factor = 0.5

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Newton After Iterations = 10000

Steady State Convergence Tolerance = 1.0e-5

End

Solver 3

Equation = "HeatEquations"

Procedure = "HeatSolve" "HeatSolver"

Variable = "Temperature"

Exec Solver = "Always"

Stabilize = True

Optimize Bandwidth = True

Linear System Solver = Iterative

Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 500

Linear System Convergence Tolerance = 1.0e-8

Linear System Preconditioning = ILU0

Linear System Precondition Recompute = 1

Steady State Convergence Tolerance = 1.0e-5

Nonlinear System Convergence Tolerance = 1.0e-4

Nonlinear System Max Iterations = 1

Nonlinear System Newton After Iterations = 10000

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Relaxation Factor = 0.5

Steady State Convergence Tolerance = 1.0e-5

End

Equation 1

Name = "metals"

Active Solvers(1) = 3

Convection = Computed

End

Equation 2

Name = "fluid"

Active Solvers(3) = 2 1 3

Convection = Computed

End

!! ------------------------------------------------- !!

!! --- [3] body & materials --- !!

!! ------------------------------------------------- !!

Body 1

Name = "metal"

Target Bodies(1) = $metal

Equation = 1

Material = 1

Initial Condition = 1

End

Body 2

Name = "fluid"

Target Bodies(1) = $fluid

Equation = 2

Material = 2

Initial Condition = 2

Body Force = 1

End

Body 3

Name = "container"

Target Bodies(1) = $container

Equation = 1

Material = 1

Initial Condition = 3

End

Material 1

Name = "SS400"

Heat Conductivity = 51.6 !! W/m.K

Heat Capacity = 473.0 !! J/kg.K

Reference Temperature = 293.15 !! K

Density = 7.85e+3 !! kg/m3

End

Material 2

Name = "Air"

!! fluid property !!

Viscosity = 1.0e-5 !! Pa.s

Density = 1.166e+0 !! kg/m3

KE SigmaK = 1.00

KE SigmaE = 1.30

KE C1 = 1.44

KE C2 = 1.92

KE Cmu = 0.09

KE Clip = Real 1.0e-6

Viscosity Model = K-Epsilon

!! heat property !!

Heat Conductivity = 0.0257 !! W/m.K

Heat Capacity = 1.005e+3 !! J/kg.K

Reference Temperature = 293.15 !! K

Heat Expansion Coefficient = 3.665e-3 !! 1e-6

End

!! ------------------------------------------------- !!

!! --- [4] initial boundary condition --- !!

!! ------------------------------------------------- !!

$ T_metal = 473.15

$ T_fluid = 293.15

$ T_container = 293.15

Initial Condition 1

Name = "metal.initial"

Temperature = $T_metal

End

Initial Condition 2

Name = "fluid.initial"

Velocity 1 = 0

Velocity 2 = 0

Temperature = $T_fluid

Kinetic Energy = 0.00457

Kinetic Dissipation = 1.0e-4

End

Initial Condition 3

Name = "container.initial"

Temperature = $T_container

End

Boundary Condition 1

Name = "fluid.boundary"

Target Boundaries(2) = 102 103

Normal-Tangential Velocity = True

velocity 1 = 0.0

!! Noslip Wall BC = True

End

!! ------------------------------------------------- !!

!! --- [6] others --- !!

!! ------------------------------------------------- !!

Body Force 1

Name = "BoussinesqApprox"

Boussinesq = Logical True

End

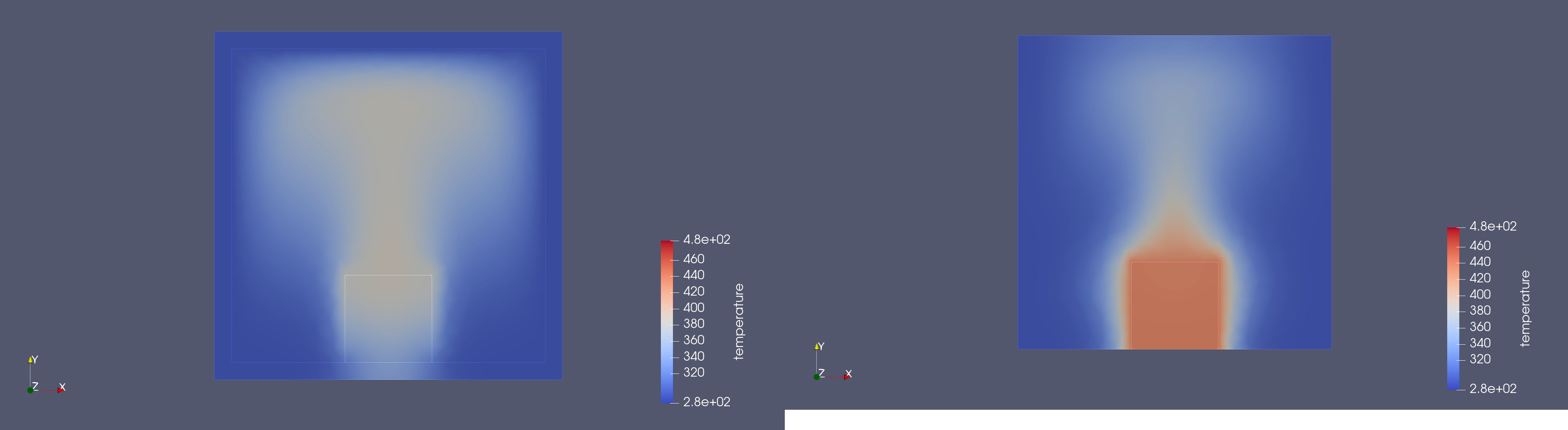

自然対流冷却のシミュレーション結果¶

温度の時間発展¶

結果について¶

鉄塊内部の温度差が顕著.

容器側へ、熱伝導で大部分の熱が逃げている可能性が高い.

容器なしでシミュレーションして比較検討してみる.

容器なしの場合との比較¶

メッシュ¶

メッシュ生成スクリプト ( mesh.py )

import numpy as np

import os, sys

import gmsh

import nkGmshRoutines.define__geometry_2d as dg2

import nkGmshRoutines.load__dimtags as ldt

# ========================================================= #

# === 実行部 === #

# ========================================================= #

if ( __name__=="__main__" ):

# ------------------------------------------------- #

# --- [1] initialization of the gmsh --- #

# ------------------------------------------------- #

gmsh.initialize()

gmsh.option.setNumber( "General.Terminal", 1 )

gmsh.option.setNumber( "Mesh.Algorithm" , 5 )

gmsh.option.setNumber( "Mesh.Algorithm3D", 4 )

gmsh.option.setNumber( "Mesh.SubdivisionAlgorithm", 0 )

gmsh.model.add( "model" )

# ------------------------------------------------- #

# --- [2] Modeling --- #

# ------------------------------------------------- #

dimtags = {}

inpFile = "dat/woContainer/geometry.conf"

bdrFile = "dat/woContainer/boundary.json"

dimtags = dg2.define__geometry_2d( inpFile=inpFile, dimtags=dimtags )

dimtags = ldt.load__dimtags( dimtags=dimtags, inpFile=bdrFile )

gmsh.model.occ.synchronize()

gmsh.model.occ.removeAllDuplicates()

gmsh.model.occ.synchronize()

# ------------------------------------------------- #

# --- [3] Mesh settings --- #

# ------------------------------------------------- #

mesh_from_config = True # from nkGMshRoutines/test/mesh.conf, phys.conf

uniform_size = 0.05

if ( mesh_from_config ):

meshFile = "dat/woContainer/mesh.conf"

physFile = "dat/woContainer/phys.conf"

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( meshFile=meshFile, physFile=physFile, \

dimtags=dimtags, target="surf" )

else:

import nkGmshRoutines.assign__meshsize as ams

meshes = ams.assign__meshsize( uniform=uniform_size, dimtags=dimtags )

# ------------------------------------------------- #

# --- [4] post process --- #

# ------------------------------------------------- #

gmsh.model.occ.synchronize()

gmsh.model.mesh.generate(2)

gmsh.write( "msh/model.msh" )

gmsh.finalize()

geometry.conf

# <define> @cntnr.Lx = 200e-3

# <define> @cntnr.Ly = 200e-3

# <define> @cntnr.thick = 10e-3

# <define> @cntnr.x0 = (-0.5) * @cntnr.Lx

# <define> @cntnr.y0 = 0.0

# <define> @cntnr.dx = @cntnr.Lx

# <define> @cntnr.dy = @cntnr.Ly

# <define> @fluid.Lx = @cntnr.Lx - 2.0 * @cntnr.thick

# <define> @fluid.Ly = @cntnr.Ly - 2.0 * @cntnr.thick

# <define> @fluid.x0 = (-0.5) * @fluid.Lx

# <define> @fluid.y0 = @cntnr.thick

# <define> @fluid.dx = @fluid.Lx

# <define> @fluid.dy = @fluid.Ly

# <define> @metal.Lx = 50e-3

# <define> @metal.Ly = 50e-3

# <define> @metal.x0 = (-0.5) * @metal.Lx

# <define> @metal.y0 = @cntnr.thick

# <define> @metal.dx = @metal.Lx

# <define> @metal.dy = @metal.Ly

# <names> key geometry_type x0 y0 dx dy

metal quad @metal.x0 @metal.y0 @metal.dx @metal.dy

fluid.00 quad @fluid.x0 @fluid.y0 @fluid.dx @fluid.dy

# <names> key boolean_type targetKeys toolKeys removeObject removeTool

fluid cut [fluid.00] [metal] True False

boundary.json

{

"metal" : [ [2,1] ],

"fluid": [ [2,2] ],

"metal_fluid": [ [1,5], [1,6], [1,7] ],

"fluid_outside": [ [1,1], [1,2], [1,3], [1,4], [1,8] ],

"metal_outside": [ [1,9] ]

}

phys.conf

# <names> key type dimtags_keys physNum

metal surf [metal] 201

fluid surf [fluid] 202

metal_fluid line [metal_fluid] 101

fluid_outside line [fluid_outside] 102

metal_outside line [metal_outside] 103

mesh.conf

# <names> key physNum meshType resolution1 resolution2 evaluation

metal 201 constant 0.01 - -

fluid 202 constant 0.01 - -

metal_fluid 101 constant 0.0 - -

fluid_outside 102 constant 0.0 - -

metal_outside 103 constant 0.0 - -

容器なしの場合のシミュレーション設定¶

elmer シミュレーション設定ファイルを以下に示す.

!! ========================================================= !!

!! === time-evolution of natural cooling by Boussinesq === !!

!! ========================================================= !!

include "./msh/model/mesh.names"

Header

CHECK KEYWORDS Warn

Mesh DB "." "msh/model"

Include Path ""

Results Directory "out/"

End

!! ------------------------------------------------- !!

!! --- [1] Simulation --- !!

!! ------------------------------------------------- !!

Simulation

Max Output Level = 3

Coordinate System = "Cartesian"

Coordinate Mapping(3) = 1 2 3

Simulation Type = "Transient"

TimeStepping Method = BDF

BDF Order = 2

Timestep sizes(1) = 5e-2

Timestep Intervals(1) = 500

Steady State Max Iterations = 200

Post File = steady_ke.vtu

End

Constants

Stefan Boltzmann = 5.6703e-8 !! -- [ W / m^2 K^4 ] -- !!

gravity(4) = 0 -1 0 9.82 !! -- [ m/s^2 ] -- !!

End

!! ------------------------------------------------- !!

!! --- [2] Solver & Equation --- !!

!! ------------------------------------------------- !!

Solver 1

Equation = k-epsilon

Procedure = "KESolver" "KESolver"

Stabilize = True

Linear System Solver = Direct

Linear System Direct Method = String "umfpack"

!! Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 10000

Linear System Preconditioning = ILUT

Linear System Convergence Tolerance = 1.0e-5

Nonlinear System Max Iterations = 1

Nonlinear System Convergence Tolerance = 1.0e-5

Nonlinear System Relaxation Factor = 0.5

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Newton After Iterations = 10000

Steady State Convergence Tolerance = 1.0e-5

End

Solver 2

Equation = Navier-Stokes

Procedure = "FlowSolve" "FlowSolver"

Stabilize = True

Linear System Solver = Direct

Linear System Direct Method = String "umfpack"

!! Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 10000

Linear System Convergence Tolerance = 1.0e-5

Linear System Preconditioning = ILUT

Nonlinear System Max Iterations = 1

Nonlinear System Convergence Tolerance = 1.0e-5

Nonlinear System Relaxation Factor = 0.5

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Newton After Iterations = 10000

Steady State Convergence Tolerance = 1.0e-5

End

Solver 3

Equation = "HeatEquations"

Procedure = "HeatSolve" "HeatSolver"

Variable = "Temperature"

Exec Solver = "Always"

Stabilize = True

Optimize Bandwidth = True

Linear System Solver = Iterative

Linear System Iterative Method = BiCGStab

Linear System Max Iterations = 500

Linear System Convergence Tolerance = 1.0e-8

Linear System Preconditioning = ILU0

Linear System Precondition Recompute = 1

Steady State Convergence Tolerance = 1.0e-5

Nonlinear System Convergence Tolerance = 1.0e-4

Nonlinear System Max Iterations = 1

Nonlinear System Newton After Iterations = 10000

Nonlinear System Newton After Tolerance = 0.0

Nonlinear System Relaxation Factor = 0.5

Steady State Convergence Tolerance = 1.0e-5

End

Equation 1

Name = "metals"

Active Solvers(1) = 3

Convection = Computed

End

Equation 2

Name = "fluid"

Active Solvers(3) = 2 1 3

Convection = Computed

End

!! ------------------------------------------------- !!

!! --- [3] body & materials --- !!

!! ------------------------------------------------- !!

Body 1

Name = "metal"

Target Bodies(1) = $metal

Equation = 1

Material = 1

Initial Condition = 1

End

Body 2

Name = "fluid"

Target Bodies(1) = $fluid

Equation = 2

Material = 2

Initial Condition = 2

Body Force = 1

End

Material 1

Name = "SS400"

Heat Conductivity = 51.6 !! W/m.K

Heat Capacity = 473.0 !! J/kg.K

Reference Temperature = 293.15 !! K

Density = 7.85e+3 !! kg/m3

End

Material 2

Name = "Air"

!! fluid property !!

Viscosity = 1.0e-5 !! Pa.s

Density = 1.166e+0 !! kg/m3

KE SigmaK = 1.00

KE SigmaE = 1.30

KE C1 = 1.44

KE C2 = 1.92

KE Cmu = 0.09

KE Clip = Real 1.0e-6

Viscosity Model = K-Epsilon

!! heat property !!

Heat Conductivity = 0.0257 !! W/m.K

Heat Capacity = 1.005e+3 !! J/kg.K

Reference Temperature = 293.15 !! K

Heat Expansion Coefficient = 3.665e-3 !! 1e-6

End

!! ------------------------------------------------- !!

!! --- [4] initial boundary condition --- !!

!! ------------------------------------------------- !!

$ T_metal = 473.15

$ T_fluid = 293.15

Initial Condition 1

Name = "metal.initial"

Temperature = $T_metal

End

Initial Condition 2

Name = "fluid.initial"

Velocity 1 = 0

Velocity 2 = 0

Temperature = $T_fluid

Kinetic Energy = 0.00457

Kinetic Dissipation = 1.0e-4

End

Boundary Condition 1

Name = "fluid.boundary"

Target Boundaries(2) = 101 102

Normal-Tangential Velocity = True

velocity 1 = 0.0

!! Noslip Wall BC = True

End

!! ------------------------------------------------- !!

!! --- [6] others --- !!

!! ------------------------------------------------- !!

Body Force 1

Name = "BoussinesqApprox"

Boussinesq = Logical True

End

容器の有無による温度分布の差異 ( t=25 (s) 経過後 )¶

比較した結果について¶

明らかに容器を伝って熱伝導により、熱が逃げているのがわかる.